Cell phone towers are everywhere. At the base of each tower is a small “machine” room that houses all the telephone equipment needed for the site. Most of this equipment is electronic and it is important that it keeps running no matter what – we can’t stop playing our Pokémon Go…

Actually, cell-based telephone service is a robust service that is a world unto itself. The machine rooms are full of industrial-grade equipment meant to take a beating and provide service under extreme conditions. One of those conditions is loss of power. This means that each machine room has an extensive battery backup system in addition to all the communications and computer electronics.

All this equipment generates a lot of heat. Industrial air conditioning systems are used to keep the temperature inside the building optimum for the electronics. The AC runs even in winter!

Maintaining temperature control in this environment is nothing new – except this is not the complete story. Cell phone tower machine rooms are special for several reasons:

- The towers are placed as far apart as possible.

- If possible, the towers are placed where people don’t want to be.

- Changing seasons must never be a problem.

- No one is there to be sure everything is OK. They operate unattended as much as possible. In fact, it is so expensive to have a person visit each location that extra effort and redundancies are built into every component to maximize reliability and minimize service needs.

- Air conditioning must be oversized to be sure the electronics never overheat.

- However, cooling efficiency is important to help keep the operating costs of the cell tower as low as possible.

All these extra constraints tend to force a traditional air conditioning temperature control computer to operate beyond optimal setting. Imagine an air conditioning system designed with a huge margin of safety for cooling unusually hot, hardworking equipment on an unusually hot day – then asking that same system to cool unusually cool, idle equipment on an unusually cold night. It’s like using a sludge hammer to push in a thumbtack. In this case it is both economically inefficient and mechanically bad for the air conditioning system.

Sometimes the operational range is so large that two separate air conditioning systems must be installed. One system for high cooling loads and one for smaller cooling loads. This is expensive.

Somewhere between the two cases is designing a temperature controller that understands the situation better to wisely extend the operational range of a single, oversized air conditioning system.

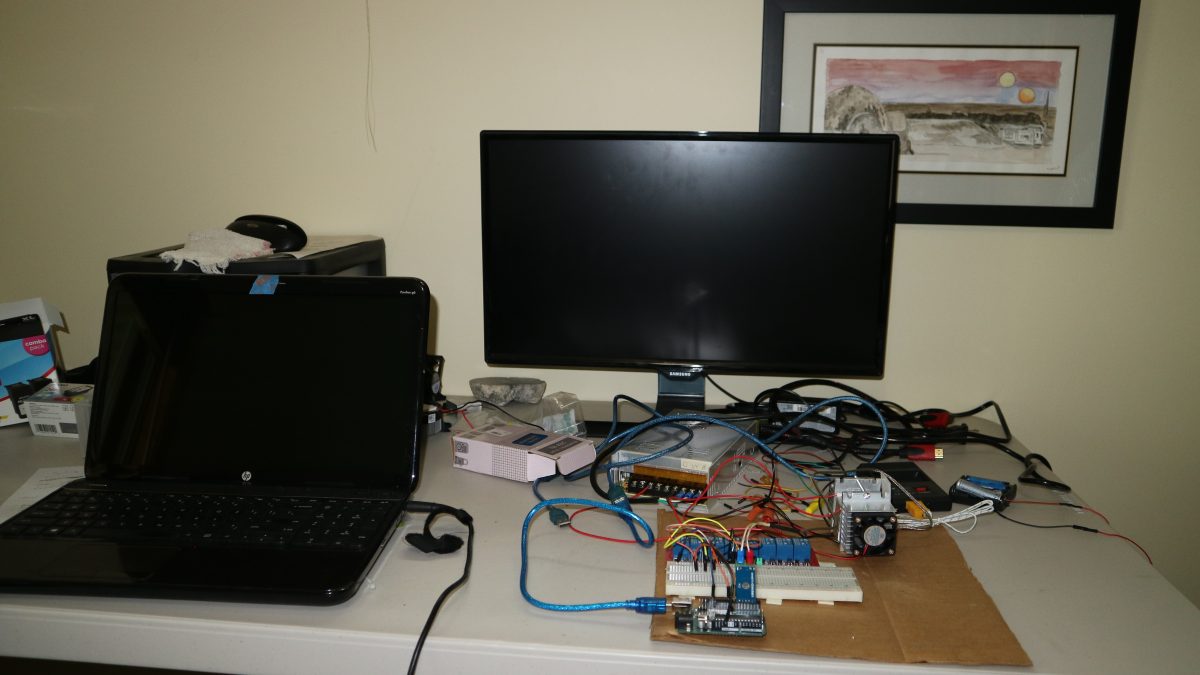

This prototype is an Arduino-based prototype that does just that. Using existing equipment, the software uses a general mathematical model of the physical system to implement multiple PID controller functions, and well-understood electromechanical system limitations, to extend the operational range of the air conditioning system and operate it as economically efficient as possible.

A separate project is the test jig to model a physical air conditioning system in my little office.

The final goal is to reduce the temperature controller system to this tiny temperature controller board.

Check out the Thermoelectric Peltier Device Air Conditioning Equipment Simulator post.